Description

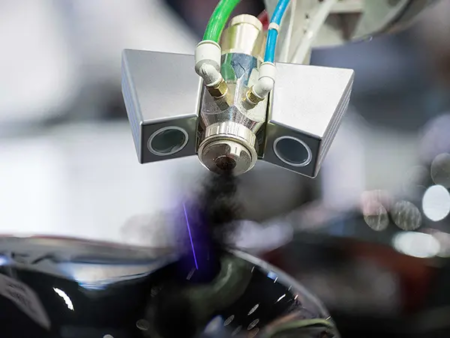

SpraySpy® ProcessLine sensor systems are specifically developed for inline quality monitoring and process automation in industrial coating applications—making them truly unique.

These instruments measure and digitize key spray quality parameters. The data is analyzed in real time using AI-powered SprayAI® algorithms that automatically detect even the smallest anomalies—essential for a fully digital coating process and modern, intelligent paint shop.

SpraySpy® spray monitoring can help prevent up to 60% of the most common paint defects, according to the “Trendbarometer by besserlackieren” (Issue 03/2019).

The systems are designed for seamless inline integration, enabling automated 24/7 quality monitoring. The embedded SprayAI® software classifies each spray in real time as OK or NOK during operation.

All monitoring data is logged and can be used for further applications such as smart maintenance, closed-loop spray control, or building a digital twin of your coating process.

SpraySpy® integrates several patented innovations, making it easy to operate and a reliable upgrade for your quality control and process automation.