Description

The cabinet is developed and designed as the original Volvo Tropical Cabinet to conform the test standards from Volvo Group, STD 423-0018 and Volvo Car, VCS 1027,33759. It is essential for these tests that the cabinet design is kept to the original format and type of materials etcetera.

It is also possible to perform the different test in the ISO 6270-2 standard although the CH, constant temperature, and AT, fully condensation with temperature change, is possible to perform fully automatic but the AHT, changing condensation and temperature, can be performed semi-automatic. This means for the AHT cycle the the door periodically opened.

ControlArt, have experience from both developing the tropical test with fully automatic control and refilling the cabinet with fresh water periodically and automatically in order to avoid salt and dirt accumulations.

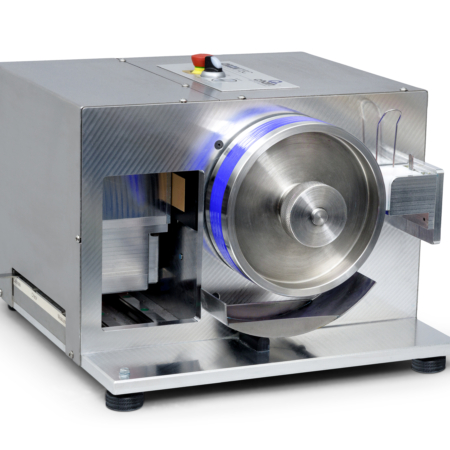

The HC 100 equipment has been further developed from the original tropical cabinet.

Fully automatic control system in line with the latest trends in industrial automation, i.e. PLC with data memory and touchscreen interface.

You can operate the test system without an external PC.

With a connected PC and the software developed by ControlArt, it is possible to freely add further test cycle standards. You can also monitor the device in parallel to the touchscreen with the device. You can receive either text or Excel reports on historical run data and also retrieve diagnostic files. The reports and diagnostic data as well as updating the software on the machine can also be done via a USB port on the device.

In the system, you can fill and drain the water level manually or program-controlled, or both.

An automatic function for maintaining the fill level without disturbing the running performance is included.

A watchdog allows access to the device for sample changes etc. Here, the heating is switched off during opening in order to maintain the curve in the best possible way.

Interested? Contact us Now!